How to tell if “N52” Neodymium Magnets are Real

Expect that all magnets from AliExpress are N35. However, if a store on AliExpress advertises its magnets as N50 ~ N52, I want to hold them accountable and get a partial refund and stop sellers from cheating.

What follows are five at-home methods to determine Neodymium magnet strength.

Here I outline five at-home test methods to show the strength of a magnet so you can dispute AliExpress sellers with ferrous-clad proof.

- Relative Magnetic Pull-Force Meter

- Point-Flux Lifting-Force Meter

- Binary Magnetic-Strength Comparator

- Maximum Air-Contact Flux-Density Meter

- Induced Magnetic DC-Bias Meter

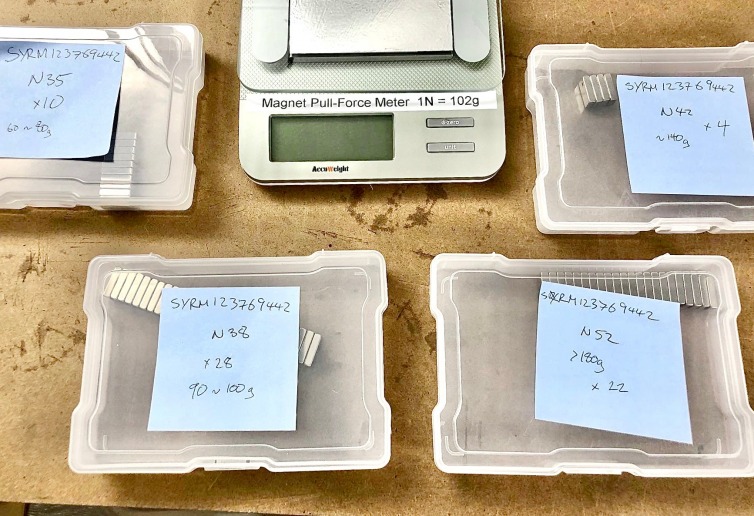

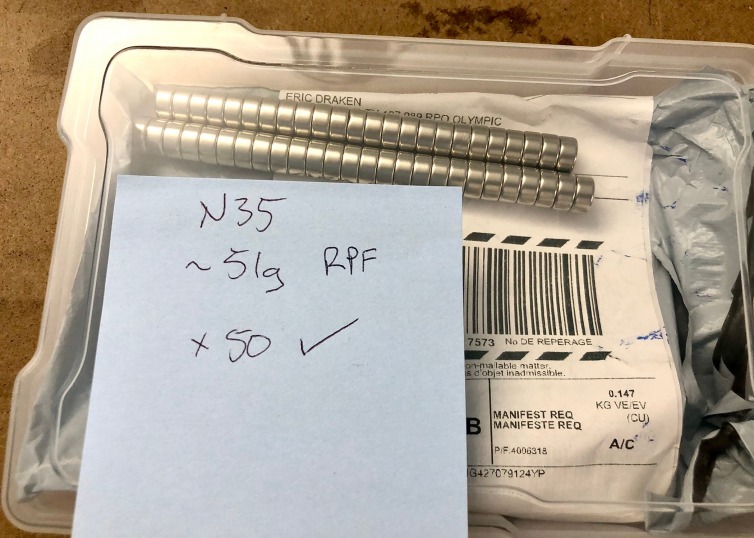

Test Magnet Inventory and Measurements

As of May 2022, here is my magnet inventory. Here, N* is the advertised grade, not the true grade. In the remarks, I state if I got a partial refund for that false magnet-grade advertisement. Where The remark is “Fake?”, the magnet is too small and the outer nickel-copper coating thickness is non-negligible, but the max air-contact gauss (MACG) reading is quite low.

All dimensions are in mm unless otherwise stated.

| L | W | Dia. | H | Qty | Pull (g) | Flux (Gs) | Vol (mm³) | SA (mm²) | N* | Remarks |

|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 5 | 50 | 172 | 3400 | 883.5 | 176.7 | 35 | N35 Ok | ||

| 10 | 5 | 100 | 61 | 3500 | 392.5 | 78.5 | 35 | N35 Ok | ||

| 10 | 10 | 10 | 27 | 190 | 3500 | 1000 | 100 | 35 | N35 Ok | |

| 20 | 10 | 5 | 40 | 110 | 2900 | 1000 | 200 | 52 | Fake – Refund | |

| 100 | 10 | 5 | 5 | 390 | 2600 | 5000 | 1000 | 50 | Fake | |

| 20 | 10 | 5 | 14 | 80 | 2300 | 1000 | 200 | 52 | Fake – Refund | |

| 20 | 10 | 5 | 10 | 140 | 2700 | 1000 | 200 | 52 | Fake – Refund | |

| 20 | 10 | 5 | 50 | 100 | 2500 | 1000 | 200 | 52 | Fake – Refund | |

| 20 | 10 | 5 | 30 | 180 | 3200 | 1000 | 200 | 52 | Fake – Refund | |

| 10 | 5 | 50 | 61 | 3500 | 392.5 | 78.5 | 52 | Fake – Refund | ||

| 5 | 5 | 4 | 400 | 7 | 2600 | 100 | 25 | 52 | Fake | |

| 10 | 3 | 100 | 32 | 2400 | 235.5 | 78.5 | 52 | Fake? | ||

| 10 | 2 | 146 | 16 | 1500 | 157 | 78.5 | 52 | Fake? | ||

| 10 | 5 | 5 | 50 | 20 | 2800 | 250 | 50 | 35 | N35 Ok | |

| 10 | 5 | 10 | 41 | 2500 | 392.5 | 78.5 | 35 | N35 Ok | ||

| 5 | 5 | 5 | 100 | 8 | 3000 | 125 | 25 | 35 | N35 Ok | |

| 10 | 5 | 3 | 100 | 14 | 2400 | 150 | 50 | 35 | N35 Ok | |

| 40 | 40 | 20 | 4 | 1200 | 6000 | 32000 | 1600 | 52 | Real? |

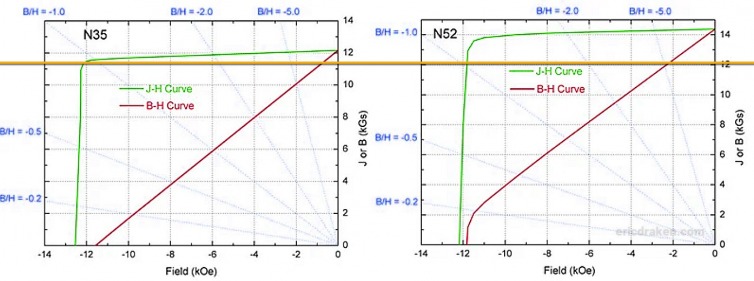

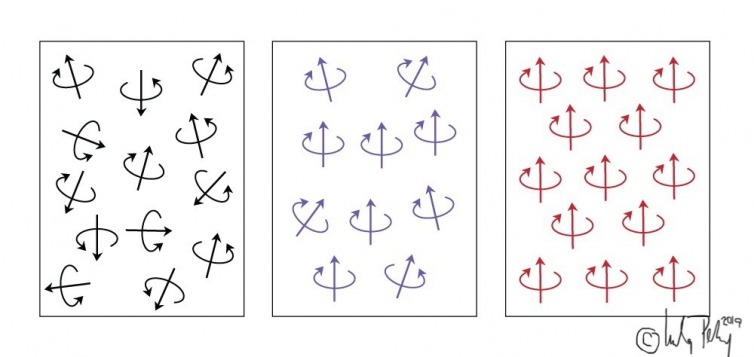

Manufacturing Differences Between N35 and N52

Before we begin, what makes a neodymium magnet weak or strong?

Neodymium magnets are very strong – even N35 magnets. It is hard to pull apart both N35 and N52 magnets, so it is tough to tell which is which just by pulling them apart. Yet, N52 magnets are 50% stronger than N35 magnets (52/35 = 1.49), so we want to identify them.

Nd2Fe14B or Neodymium-Iron-Boron magnets can be sintered or bonded. Bonded magnets are about half as strong as sintered magnets, but can take on complex shapes.

| Magnet1 | Br (T) | Hci (kA/m) |

|---|---|---|

| Nd2Fe14B, sintered | 1.0–1.4 | 750–2000 |

| Nd2Fe14B, bonded | 0.6–0.7 | 600-1200 |

Almost all sintered NdFeB magnets can only be magnetized in their crystal orientation direction. In general, magnetizing fields of about 30 KOe2 are required to saturate NdFeB magnets.

In practice, the magnetic properties of neodymium magnets depend on the microstructure and manufacturing technique1. Could these “N52” magnets have been manufactured using shortcuts?

What do Neodymium Grades Mean?

Here is essentially the difference between N35 and N52 magnets3:

In short, higher N-grade neodymium magnets have a higher flux density, higher energy density, and better resistance to demagnetization: more flux in less volume.

So then, how can we empirically differentiate between an N35 and N52 magnet to get a partial refund from sellers?

Here are my five devices to determine magnetic strength at home.

1. Relative Magnetic Pull-Force Meter

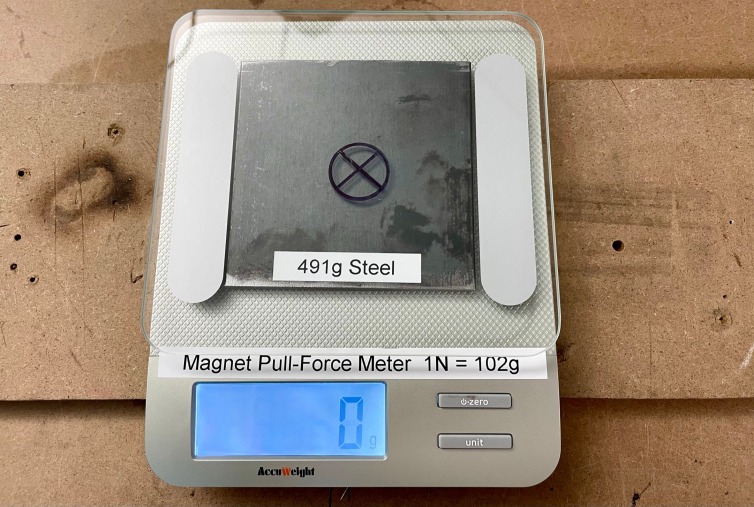

If we can measure the force of attraction between a magnet and a steel plate, we can calculate the pull force for a given volume and contact surface area of a magnet. The pull force is also the maximum weight a naked magnet can lift.

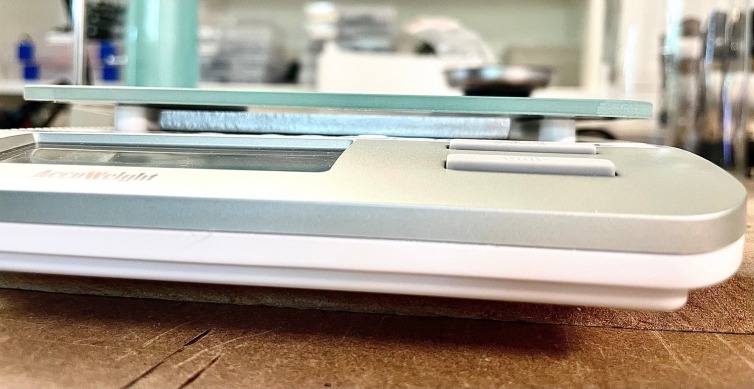

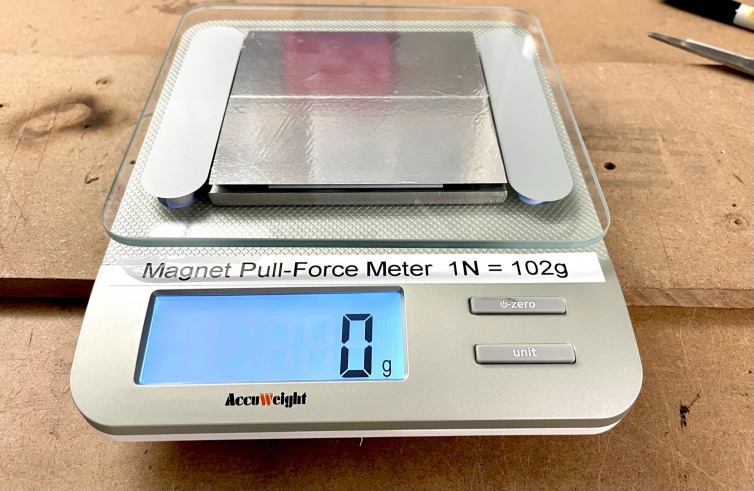

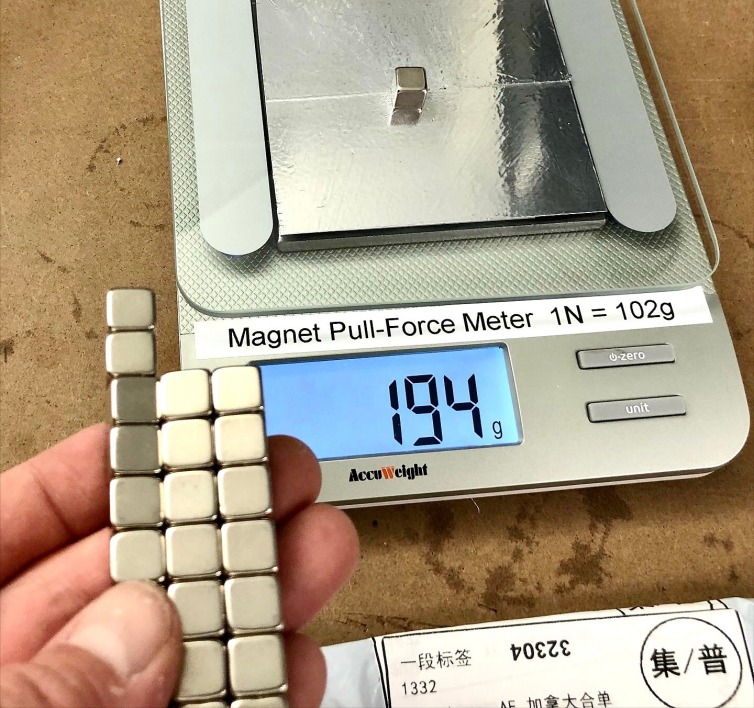

To do this, I purchased a gram scale with a glass bed that has space for a steel plate beneath it but above the electronics bed; this steel should shield the components in the scale. This is my permanent magnet pull-force gauge (forgive the wordplay).

When the plate is glued to the electronics bed, its weight can be ignored; it should be large enough to not be saturated with flux for larger magnets.

Conveniently, when testing same-sized magnets, the weight of the actual magnet can be ignored due to the relative pull-force comparison.

Calibrate the Pull-Force Meter

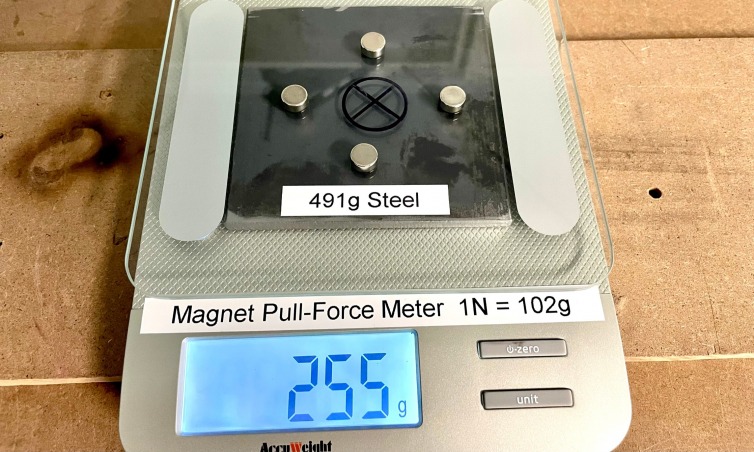

After gluing the plate to the electronics bed with a combination of cyanoacrylate (i.e. Krazy Glue) for an instant bond coupled with Gorilla Glue (industrial polyurethane adhesive) for a powerful bond, let’s test that the pull force increases proportionally with the addition of identical magnets.

Right away we can see the effectiveness of this simple magnetic pull-force meter.

You’ll quickly notice that you should protect the glass bed from scratching when sliding off magnets between tests. I recommend 3.6 mil aluminum tape.

Uncover Variability Within a Batch

Assume you do not have a genuine, high-grade N52 magnet to test with; you do not need one. Start by measuring one magnet in the batch and keep note of the pull force. When you arrive at a significantly stronger or weaker magnet, you’ve hit on something.

All magnets should have the same relative pull force within a few percent. If you find even one that is significantly stronger or weaker, then you can already show the retailer their magnets vary internally.

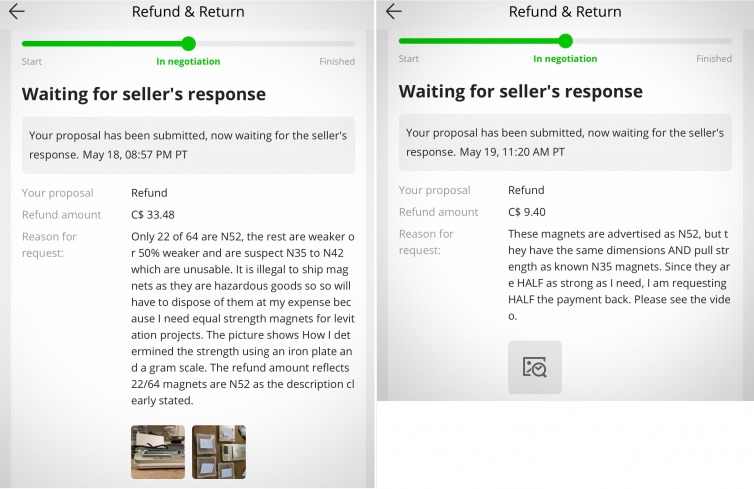

Below is a real example of a huge pull-force variation between magnets in a batch of 64 magnets from AliExpress. The variation is from 60 g to over 180 g in a batch of maladvertized N52 magnets.

N52 magnets should be twice as strong as N35 magnets, so the fact that there is a thrice pull-force difference makes me very suspicious of these magnets.

Order Weak N35 Magnets on Purpose

On purpose, order the weakest, cheapest N35 magnets of the exact dimensions as the “N52” magnets you truly want. Order a couple dozen or more and take an average of the pull force, but remove any wide outliers. You should then have a pretty good idea of what N35 pull force is.

Check Magnets Against Known N35 Samples

It is challenging to find an authentic N52 magnet to compare other magnets with; you could be very unlucky and keep receiving low-grade, maladvertized magnets, and the shape may not be compatible with those under test.

This is another case that happened to me: all my “N52” magnets had the same pull force. Hooray. They must be N52, right? Not so fast. I checked them against my N35 magnets from a different seller (N35 is the weakest neodymium magnet grade) and they have nearly identical pull forces:

I proved I did not receive N52 magnets.

2. Point-Flux Lifting-Force Meter

This is just a fancy name for a tube that has steel balls in it so we can see how many a magnet can lift.

Stronger magnets lift more steel balls against gravity.

The term “point flux” is to the fact that all the steel bearings contact tangentially, or at a point, with each other. This means the surface area of the magnet under test does not affect the pull force of a steel ball held at a point on the magnet.

The device looks like this:

For instance, I note that the stronger “N52” magnets from the previous example hold 6 bearings on average, while the weaker “N52” magnets hold about 4 bearings on average. That’s a 50% lift-force difference. This is to be expected because N35 magnets are about 50% weaker than N52 magnets.

A strong block magnet can hold many bearings.

3. Binary Magnetic-Strength Comparator

What if you would just like to know which of two magnets are stronger so you can perform a binary sort on real objects? One magnet will always be stronger, if just slightly, than another magnet.

Here is a device whereby a lubricated Neodymium magnet is free to slide in a sealed tube, and it will jump to the weaker magnet under these circumstances:

- Center the magnet in the tube.

- Place magnet A on the left of center, and magnet B on the right.

- Flip magnet A so it pushes away the center magnet. Same for magnet B.

- Move both magnets closer and closer to the center of the tube magnet.

The tube magnet will jump to the weaker magnet because it cannot overcome the repulsive force of the stronger magnet.

The weaker magnet jumps to the next local stable state which is one having its poles aligned with the weaker magnet in a strong fixed position. This way, we can quickly tell which magnet is stronger even if they are quite similar in strength.

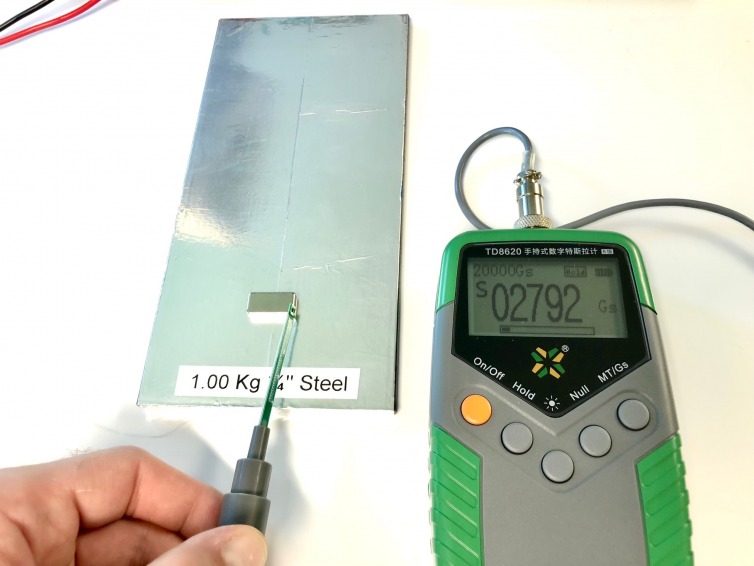

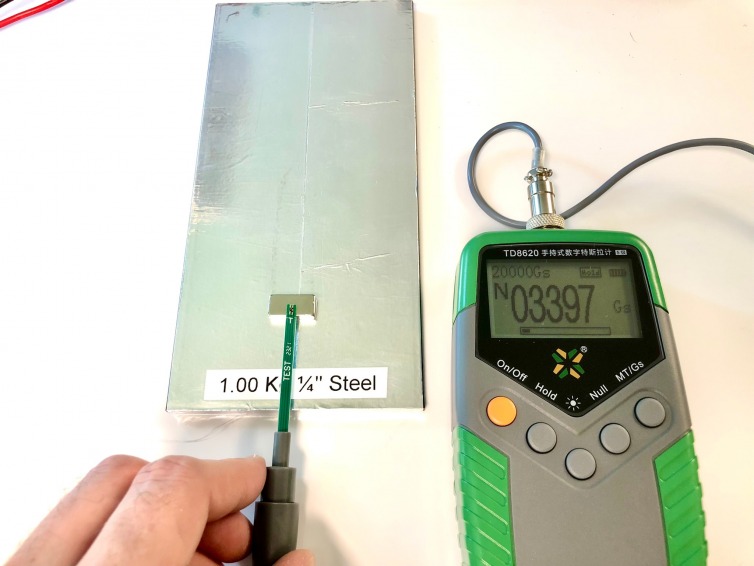

4. Maximum Air-Contact Flux-Density Meter

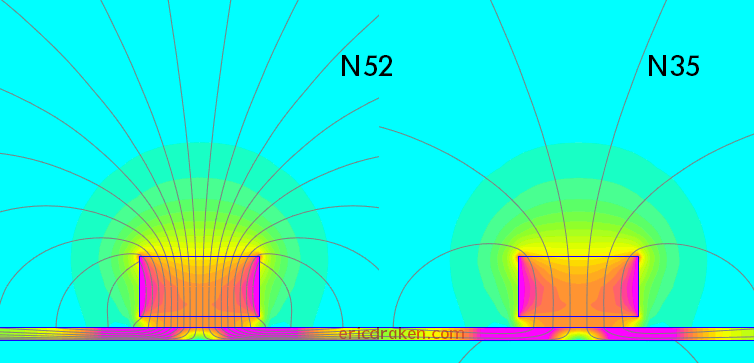

Here is the idea of the manifestation of a measurable difference between N52 and N35 magnets.

The reason why same-size magnets with the same chemical composition have different flux densities is due to manufacturing. Simply put, the more Nd2Fe14B lattice crystals that have the same alignment, the more electrons that have the same spin and orientation, so the stronger the net flux becomes.

If you have a Gauss meter (also known as a gaussmeter or magnetometer) handy, you can measure the magnetic flux density at a point on or near the magnet under test. Stronger magnets have a higher flux density. Use a Gauss meter to get one reading for one magnet, another reading for another magnet, then compare.

Why was this not proposed as a testing solution first? This test requires some finesse to pull off because the HAL-effect (flux density) sensor is a point sensor but the magnet has area and edges.

Put another way, “lines” of magnetism must follow the easiest path (lowest reluctance) to form a closed loop without crossing. That is why magnets feel stronger at their edges rather than the center of their poles. To get the highest possible air-contact flux density reading, I use a thick steel plate under the magnet.

Note: Do not crush your expensive probe between the steel plate and the magnet, hence “air-contact”.

For this test, rather than eyeballing the center of a magnetic pole and touching a HAL-effect probe, set the Gauss mater to hold at the maximum value and move the probe all around the magnet. Touch the edges, corners, and sides – perform a full sweep. Note the strongest flux reading in militeslas (mT) or gauss (G).

Is the difference between 2792 Gs and 3397 Gs big?

Whatever one gauss means to you and me, one magnet has 20% more maximum air-contact flux density than the other in the experiment above – enough to show the magnets are not the same strength and to file a dispute.

Here is a video on how I found the maximum air-contact flux density of two magnets.

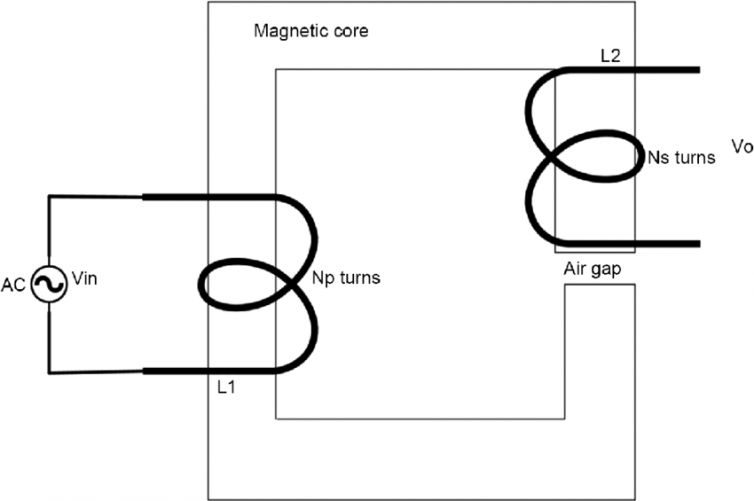

5. Induced Magnetic DC-Bias Meter

This technique is outside the box: take a two-winding ring transformer (1:1 ratio) with a large air gap and place the magnet under test inside the air gap. The magnet should stick to one end of the gap or the other.

Why is this?

In one phase of the L1 energizing, the magnet in the air gap is in the flux path of the transformer, so it either aids or opposes the flux from L1. In the second phase, the same thing: it either opposes or aids the flux from L1.

Connected to an oscilloscope, L2 will show an out-of-phase AC waveform with a DC bias: a higher bias means a stronger magnet in the air gap.

Let’s File Some Disputes

I stockpile neodymium magnets for levitation experiments, so it is critical that the pull force is nearly identical in a cluster of chosen magnets. Even if you don’t want to file a dispute, you can use the simple kitchen-scale meter to sort magnets by pull force.

Some of my orders of magnets were perfect. For example, here is a 27-magnet order of 10x10x10 mm N52 magnets that all had about 194 g to 198 g of pull force. Very nice.

However, I had to dispute magnets with other sellers on AliExpress. Here is an example of where 200 magnets were advertised as N52, but somehow they are weaker than known N35 magnets of the same size.

Here are some of the disputes I’ve filed for other magnet orders.

Side note: It is really hard to type properly in the AliExpress app’s text areas. Sorry about that.

Summary

After Googling “how can I tell if my magnets are fake?” I found just one video of a gentleman who used a CRT (old TV) to visualize the electron deflection when placing strong magnets at the screen. He used a guaranteed-authentic N52 magnet from a reputable on-soil merchant to compare that large magnet to a magnet he bought on eBay. That was expensive.

There are virtually no other search results, except for magnet vendors that swear their magnets are genuine. Or, if you have a university lab, using a Helmholtz coil to measure the torque of the magnet when it flips up is a decent test, albeit slow and careful.

This is why I sat down and thought about a couple of ways to check at home if two magnets have the same grade or not based on how magnets want to minimize the reluctance of their flux. Fortunately, with a simple kitchen scale and steel plate from Home Depot, it is easy to do just that.

Notes: